Introduction

gT-450T

Looking for the most energy efficient grain chiller for hot & humid climates?

gT grain chillers control both temperature and the relative humidity of the cooled air regardless of ambient conditions. There is no need for using highly toxic chemicals to protect the grain in storage from being damaged by insects.

10 good reasons for gT-450T

- Weather independent operation

- Maintaining harvest freshness

- No risk of fungi

- No or reduced requirement of fumigation for insects

- No discoloration of grains

- Plug and play unit

- Eliminating dry substance losses

- Moist grain can also be dried using economical drying mode

- No risk of hotspots

- High germination quality

Product Description

High quality fan guarantees most efficient heat exchange. Louvers on the side panels ensure air flow and restrict water entering the unit.

Highly reliable combination of semi-hermetic compressor with automatic capacity regulation and heavy duty heat exchangers using environmentally friendly refrigerants.

High performance speed controlled blower for optimized air flow. Fan speed is adjusted automatically through variable frequency drive.

Completely sealed electrical cabinet with state-of-the-art switchgear and control devices.

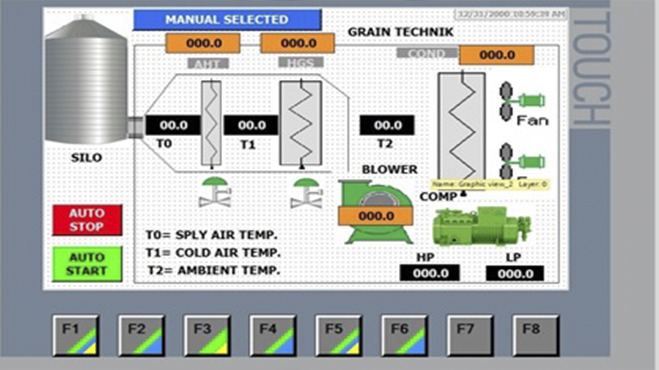

User interface equipped with latest technology touchscreen display.

Technical Specification

Compressor rating

220 kW

Cooling performance

460-750 t/Day

Refrigerant (Different refrigerants are available upon request.)

R- 407C

Design Conditions

Ambient temperature

30 °C

Evaporating temperature

10 °C

Condensing temperature

40 °C

Relative humidity

52 %

Power supply (Different voltages and frequencies are available upon request.)

415V-50Hz

Mechanical Data

Capacity

>220 kW

Max. supply airflow [m³/h]

25000 m³/h @ 1000 Pa

Connection

Chilled air interface

Ø600 mm

Dimension

Dimensions with tyres (L*W*H)

3500x2280x2810 mm

Weight

With tyres

4000 kg

Operation

Cooling in a silo / warehouse

The cooled air is distributed in the silo / warehouse through a duct system in the bottom of the silo / warehouse. As the cooled and conditioned air moves up through the grain mass, the grain temperature is reduced, eventually reaching the set temperature value.

Grain being an excellent insulator, once cooled to a low temperature, will remain cool for a substantial time period.

Grains breathe during storage, which causes the reverse reaction of the photosynthesis: dry matter is lost using oxygen from the surroundings and converted into water, carbon dioxide and heat. This process is commonly known as “self-heating” of the grain, although most people are unaware of the fact that this process is linked to a loss of dry matter.

The metabolic activity of the grain depends on its temperature and moisture. The higher the temperature and the higher the moisture content, the faster the respiration reaction which means that more dry matter is lost and converted into water and heat, further increasing the grain moisture content as well as temperature, both leading to a further increase of the respiration rate.

A vicious circle that can be completely avoided if grain is stored at low moisture content and low temperatures of 15°C and below.

Grain respiration and the consequent rise in temperature and humidity also significantly increase the risk of insect infestation and create ideal conditions for insect growth and reproduction. The grain infesting insects being very temperature sensitive, multiply rapidly in temperature zones of 23-33°C. Temperature conditions of 15°C and below are best suited to prevent breeding of most insect species and temperatures of 13°C and below keep the insects in hibernation without any activity.

The development of fungus and subsequent contamination of the grain with mycotoxins are another factor contributing to wastage of grain, a process also mostly influenced by temperature, humidity of the surrounding air and grain moisture content.

When warm air meets cold grain, condensation might occur, a very frequent problem in aeration with ambient air. Moisture at the surface or in damp pockets in the bulk will lead to growth of moulds, formation of storage mycotoxins as well as sprouting, making the grain unsuitable for human as well as animal consumption. Controlling the humidity as well as the temperature can completely eliminate the problem of mould and subsequent mycotoxin formation.